Capillary Cleaning

LD Microprecision has developed the ultra fine probes that is used in the wafer testing to effectively clean the smallest capillary wire drag holes. We have carried out some development to recycle the used Wire Bond capillary to extend its lifespan by at least 75-100% depending on the touch down usage.

Capillary Unplugging Wire

Capillary unplugging wire offers an easy economical way to unplug clogged capillary. This is especially useful for engineers during bonding evaluation when the optimum process parameters are not defined yet and the gold ball tends to get clogged in the capillary holes. This can be done by simply inserting the tip of the unplugging wire from the top of the capillary and gently raises and lowers the wire within the capillary.

Advantages: Save cost, user friendly, improve machine uptime, suitable for wide range of capillary hole size.

Electronic Flame Off (EFO)

Electronic flame off is used in the wire bonding process where high quality wire bonding is of utmost important. LD microprecision design and manufacture a wide range of EFO wands that is used currently in most wire bonder models in the semiconductor industry. These includes K&S, ASM, Kaijo, Shinkawa etc. Our company seeks igh precision machining and use IRIDIUM materials to extend the life of ignition level and to ensure uniformity and stability in the process.

Wedge

Wedge is mainly used for aluminium wire / ribbon bonding. We can provide wedges for different aluminium bonding machines. We also can provide scientific selection and technical support.

Wire Cutter

We can provide wire cutters and ribbon cutters for different aluminium wire bonding machines. Our cutters are made from special alloy to ensure the robustness and sharpness with long life characteristic.

Handy Redress Tool

Handy Redress Tool is a wire correction pen which helps you to improve on your wire bonding yield and output productivity.

Precision Part

Solder Paste Mixing and Thawing Machine

The LD Microprecision Shaker Array Solder Paste Thawing and Mixing machine utilizes the high effecient ‘Trapezoidal’ tumbling concept that provide effective agitation to the contents. This patented concept comprises four(4) chutes specially designed each with three(3) ventilating holes that allow room air draft to be drawn inside to accelerate the thawing process of the contents. This is the most effective thawing machine in the industry.

The thawing process can be direct from the freezer (-40°C -60°C) and it will take less than 25 minutes to completely thaw to the room temperature. Thereafter, the mixing and kneading (softening) process will continue to the next 20 minutes. This latest model is PLC pre-programmed to spin alternatively to accelerate both thawing and mixing process.

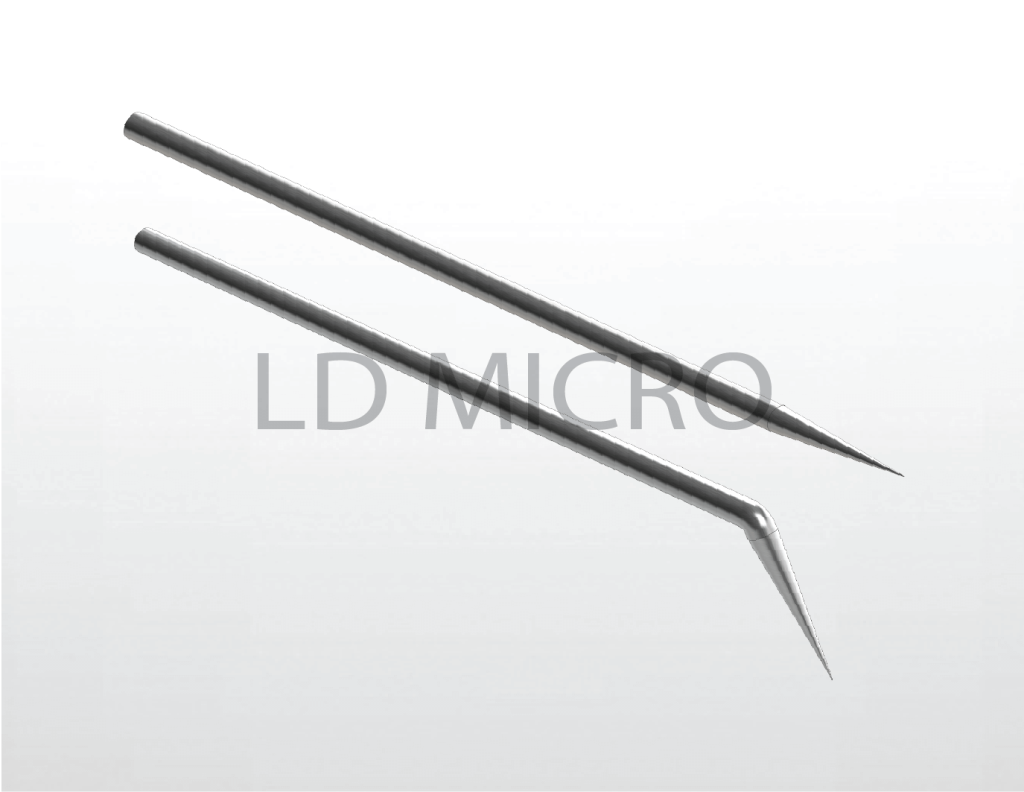

Test Probes

LD Microprecision designs, manufactures, and markets a wide range of test probes (both cantilever & blade) commonly use in the die-sort and wafer mapping process. Our specially designed equipments and proprietary processes enable us to produce ultra fine probes with tight tolerance specification to ensure effective and long lasting applications. Tips radius down to six(6) microns can be maintained.

Material: Tungsten Rhenium (WR), Tungsten (W), Beryllium Copper (BeCu), Paliney 7 (P7)

Sizes: 0.20mm (8mils), 0.25mm (10mils), 0.50mm (20mils)

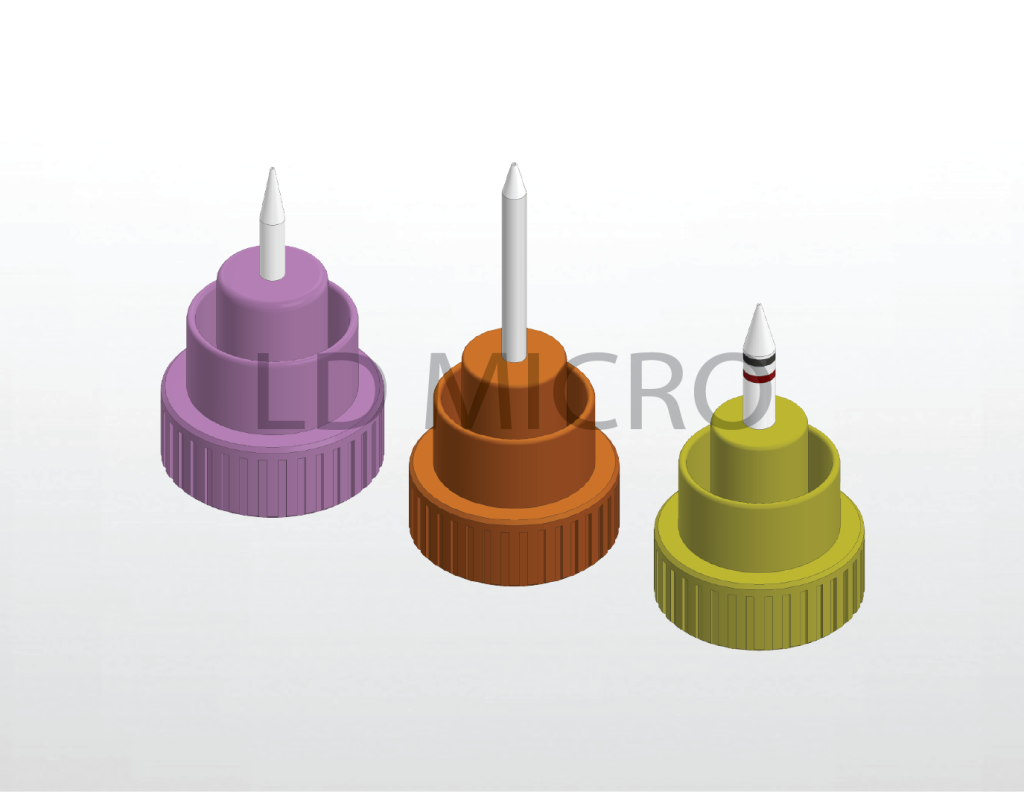

Epoxy Dispensing Tool

Epoxy dispensing tools deposit epoxy onto the die pad before a pick-up tool places a die on it. The dispensing tool has basically 2 parts – a stem with a luer-lock head which goes into the syringe containing the epoxy, and a body which has reservoir to contain the epoxy in the dispensing tool. The dispensing tools comes in different shapes.