LD Microprecision Sdn Bhd (794286-M) incorporated in 2008 has since grown and evolved into a company that is synonymous with the semiconductor assembly and bond test tools. The management team has a combined technical expertise of over 40 years in the related fields. We design, manufacture and market wide range of micro precision components used in the semiconductor, disk drive, medical, automotive and other industry. We have a global network with revenue coming mainly from Asia Pacific regions. Our company business policy is to continue providing both technology and cost down solutions to the industry we serve. Our strong R&D section will be actively involve in supporting this policy. We are ISO 9001:2015 Certified Company.

Corporate Statement

Design & Application

Substantial investment in the latest design software application enable us to design complex tools. Customised designs as per user specification are most welcome.

Sales & Marketing

Our well trained sales personnel responsible for both local and oversea sales & services support. All inquiries will be attended and response within 24 hours. For oversea market, we are well represented by distributors and agents.

Research & Development

LD Microprecision has an on-going new or improve product development program to support our corporate policy on product innovation and customers satisfaction.

R&D facilities includes:

| i. Micro Wire EDM | iv. Lapping and Polishing Machine |

| ii. Micro Brazing Station | v. High Speed Micro Drilling |

| iii. Laser Welding | vi. Complex Micro Grinding Machine |

Microline Production

Our organised Microline™ production utilises proprietary design equipments coupled with well refined process capability enable us to meet the most customers stringent standards.

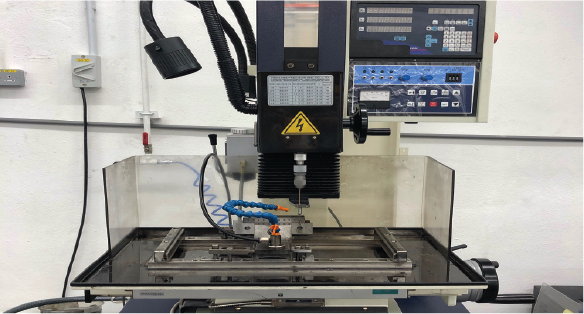

CNC Production

Continuous investments in advanced CNC equipments enable us to produce high volume production part with emphasis an quality and repeatability. Automated processes enable us to lower production cost which will benefit our customers.

Human Resource Development

We have on-going program to upskill the company employees through both theoretical and product training under our Training & Certification Program.

Our products application training is extended to all our global agents / distributors regularly.

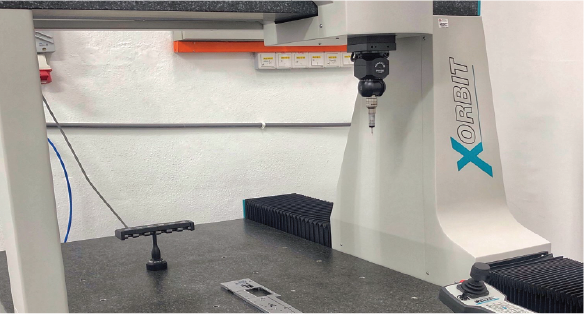

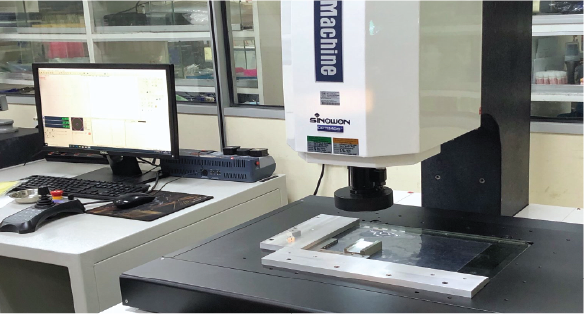

Quality Assurance

Fully equiped wih the latest advanced optical measurement systems ranging from lower power 40x to over 500x magnification. All parts shipped to our customers are accompanied with “Certificate of conformance” (COC) report.

MANUFACTURING EQUIPMENTMANUFACTURING EQUIPMENT

| Equipment | Brand | Model | Unit | Accuracy(mm) |

|---|---|---|---|---|

| CNC Milling | Yamasaki | Giken | 2 | ±0.005 |

| CNC Milling | Fanuc | @-D21MiB | 3 | ±0.010 |

| CNC Milling | Brother | TC-20A | 5 | ±0.010 |

| CNC Autolathe | Citizen | A20 | 1 | ±0.005 |

| Wirecut | Sodick | ALN400G SPW | 1 | ±0.003 (wire ⌀ 0.05) |

| Wirecut | Sodick | AQ325L | 1 | ±0.003 (wire ⌀ 0.10) |

| EDM | Sodick | AD35L | 1 | ±0.003 |

| EDM | Sodick | AL40G | 2 | ±0.003 |

| Surface Grinding | Okamoto | ACC450 | 1 | ±0.005 |

| Universal Grinding | MPG | LS-20A | 15 | ±0.005 |

| Universal Grinding | MPG | LS-20B | 3 | ±0.005 |

| Universal Grinding | MPG | LP-100 | 2 | ±0.050 |

| Universal Grinding | MPG | LH-20H | 2 | ±0.020 |

| Superdrill | AD Spark | 2030F | 1 | ±0.050 |

| Conventional Milling | UMEQ | YSM-16SS | 2 | ±0.050 |

| Conventional Turning | Schaublin | 102N | 1 | ±0.050 |

QA EQUIPMENT

| Equipment | Brand | Model | Unit | Accuracy(mm) |

|---|---|---|---|---|

| CMM | Wenzel | Xorbit55 | 1 | ±0.003 |

| CNC Vision Measurement System | Optimus Sinowon | OP-MVS-3020 | 2 | ±0.003 |

| Vision Measurement System | Optimos | VCS250 | 1 | ±0.003 |

| Vision Measurement System | Nikon | 44B | 1 | ±0.003 |

| Profile Projector | Jaten | HB16 | 2 | ±0.005 |

| Profile Projector | Optimus Sinowon | OP-PH400-3015 | 1 | ±0.005 |

| Height Gauge | Trimos | V5-400 | 1 | ±0.003 |

| Hi Power Microscope | Olympus | STM-UM | 2 | ±0.003 |

| Low Power Microscope | Optimus | – | 20 | – |

| Microscope with HD Display | Optimus | OP-7000 | 1 | – |

| Block Gauge | Optimus | – | 1 set | ±0.002 |

| Pin Gauge | MV Tech | – | 10 set | ±0.002 |

| Caliper | Mitutoyo | – | 10 | 2 decimal |

| Micrometer | Mitutoyo | – | 5 | 3 decimal |

| Equipment | Brand | Model | Unit | Accuracy(mm) |

|---|---|---|---|---|

| CNC Milling | Yamasaki | Giken | 2 | ±0.005 |

| CNC Milling | Fanuc | @-D21MiB | 3 | ±0.010 |

| CNC Milling | Brother | TC-20A | 5 | ±0.010 |

| CNC Autolathe | Citizen | A20 | 1 | ±0.005 |

| Wirecut | Sodick | ALN400G SPW | 1 | ±0.003 (wire ⌀ 0.05) |

| Wirecut | Sodick | AQ325L | 1 | ±0.003 (wire ⌀ 0.10) |

| EDM | Sodick | AD35L | 1 | ±0.003 |

| EDM | Sodick | AL40G | 2 | ±0.003 |

| Surface Grinding | Okamoto | ACC450 | 1 | ±0.005 |

| Universal Grinding | MPG | LS-20A | 15 | ±0.005 |

| Universal Grinding | MPG | LS-20B | 3 | ±0.005 |

| Universal Grinding | MPG | LP-100 | 2 | ±0.050 |

| Universal Grinding | MPG | LH-20H | 2 | ±0.020 |

| Superdrill | AD Spark | 2030F | 1 | ±0.050 |

| Conventional Milling | UMEQ | YSM-16SS | 2 | ±0.050 |

| Conventional Turning | Schaublin | 102N | 1 | ±0.050 |