-

Ball / Die Shear

Bond Test ToolsBall Shear testing is used to assess the integrity of the gold ball-to-bonding pad interface in the gold ball bonding process. A shear tool moves parallel to the bonded surface and shears the ball bond. We provide various type of ball shear to meet customers' different bond tester such as DAGE, XYZ, Royce, Rhesca and etc.

-

Capillary Cleaning

Wire BondingLD Microprecision has developed the ultra fine probes that is used in the wafer testing to effectively clean the smallest capillary wire drag holes. We have carried out some development to recycle the used Wire Bond capillary to extend its lifespan by at least 75-100% depending on the touch down usage.

-

Capillary Unplugging Wire

Wire BondingCapillary unplugging wire offers an easy economical way to unplug clogged capillary. This is especially useful for engineers during bonding evaluation when the optimum process parameters are not defined yet and the gold ball tends to get clogged in the capillary holes. This can be done by simply inserting the tip of the unplugging wire from the top of the capillary and gently raises and lowers the wire within the capillary.

Advantages: i. Save cost ii. User friendly iii. Improve machine uptime iv. suitable for wide range of capillary hole size -

Cold Bump Pull

Bond Test ToolsLD Microprecision achieved technical breakthrough in the field of complex ultrafine processes manufacturing know-how to produce the tweezer pull with tight tolerance and uncompromising performance results. Application for both solder bump and Wire Bond ball bond vertical pull.

-

Electronic Flame Off (EFO)

Wire BondingElectronic flame off is used in the wire bonding process where high quality wire bonding is of utmost important. LD microprecision design and manufacture a wide range of EFO wands that is used currently in most wire bonder models in the semiconductor industry. These includes K&S, ASM, Kaijo, Shinkawa etc. Our company seeks igh precision machining and use IRIDIUM materials to extend the life of ignition level and to ensure uniformity and stability in the process.

-

Epoxy Dispensing Tool

Die BondingEpoxy dispensing tools deposit epoxy onto the die pad before a pick-up tool places a die on it. The dispensing tool has basically 2 parts - a stem with a luer-lock head which goes into the syringe containing the epoxy, and a body which has reservoir to contain the epoxy in the dispensing tool. The dispensing tools comes in different shapes.

Please contact our sales representative for customize or special design request. -

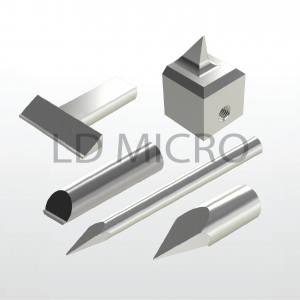

Epoxy Stamping Tool

Die BondingStamping tools are also called as transfer or printing tools because they really stamp epoxy onto the pad. Unlike the dispensing tool, the epoxy does not flow through the part and onto the pad. The tools pick up epoxy from an epoxy tray and stamps the epoxy down on to the pad. The tools come in various design such as deep groove, cross, star and single dot.

-

Handy Redress Tool

Equipment & OthersHandy Redress Tool is a wire correction pen which helps you to improve on your wire bonding yield and output productivity.

-

High Temperature Pick Up Tool

Die BondingThe Hitemp plastic pick up tools serve the purpose for assembling the small dice especially for die sizes < 25mil. The plastic material is harder then rubber material. This makes it possible to machine the tip to very small and close tolerances to enable accurate placement capabilities. LD Microprecision design, manufacture and market wide range of high-temperature pick up tool with hole size down to 80 micro & tight tolerance spec.

-

Hybrid Rubber Collet

Die BondingHybrid Rubber is one of our patented product. This collet provide easy, and reliable technique for lifting thin fragile and uneven surface die. Hybrid rubber tip can solves stack die, sticky die and foreign particles on die, and missing die issue. Other than that, its lifespan is longer than normal rubber collet.

-

Medical (Template)

Medical (Under Construction)We can design the needle holder and pepperpot according to customers' die bonding machine type, chip size and also with customers' special requirements. We can support to following die bonders now: ASM / ESEC / Datacon / Panasonic and etc.

Please contact our sales representative for more information about Pepperpot and Needle Holder configuration.

-

Needle Holder & Pepperpot

Die BondingWe can design the needle holder and pepperpot according to customers' die bonding machine type, chip size and also with customers' special requirements. We can support to following die bonders now: ASM / ESEC / Datacon / Panasonic and etc.

Please contact our sales representative for more information about Pepperpot and Needle Holder configuration.